- Home

- /

- R&D+i

R&D+I Projects

POSEIDON

POSEIDON is devised as an innovative product entailing a unified platform for the management of the instrumented systems and processes of the Integral Water Cycle and the supervision of any cybersecurity event associated with these.

Two realities that intrinsically interlinked: the supervision, control and operation of all assets in the sphere of water alongside the cybersecurity monitoring associated with any flow of information associated with latter.

Poseidon will be able to monitor and collect information representative of the processes and communication networks, and with the implementation of dynamic rules through Machine Learning (ML) and Artificial Intelligence (AI) algorithms, which will complement the static rules inherent to any monitoring system, so it will be able to improve its ability to detect possible attacks. The identification of anomalous patterns, and even typical patterns associated with an event, will provide the solution with an essential preventive capacity to ensure the integrity of the parameters that govern the correct functioning of a basic good such as water.

POSEIDON presents a milestone in the integration of cybersecurity into the operational functionalities of a product, by being able to analyse the information flows and scenarios of different operational contexts, thereby analysing not only communications yet moreover the process’s real values. This will allow us to anticipate possible cybersecurity incidents by correlating compromised situations detected through the deviation of physical or chemical parameters in any part of the water distribution network.

Proyecto: “POSEIDÓN”Project: “POSEIDON” Cybersecurity platform for comprehensive and non-intrusive protection of water management infrastructures ” Start date: 01/04/2023// End date: 31/12/2025 Budget allocated: €1,356,862 Co-financing granted: €954,911

CENTAURO

The growing global competition within the automotive components sector, alongside the trend towards the manufacture of increasingly sustainable and eco-efficient vehicles, with shorter life cycles and that include the latest technological advances, forces the European automotive components industry to strongly investigate sustainable and eco-efficient solutions that directly affect the eco-design of its products, with the aim of maximising their recyclability with the minimum environmental effect and consumption of fossil resources. This is summarised in a strong reduction in the Carbon Footprint. Research into the development of active moulds with automated degassing management systems. To implement eco-efficient production processes for ultra-lightweight seat foams for electric vehicles.

SG 2. Development of productive and automated equipment adapted to the new requirements of active melds with which to maximize the productive efficiency of VEC seats. Zero Defects.

SG 3. Research into PUR formulae that incorporate raw materials of natural and biosynthetic origin from precursors such as (vegetable oils, Bionaphtha, etc.). Carbon Footprint Reduction of VEC seats.

SG 4. Research into PPE formulae with which to achieve ultralight PPE components (d<30 g/l) for energy absorption and packaging functions of VEC elements.

SG 5. Research into BIO treatments for VEC indoor fabrics generated from recycled or natural fibres.

SG 6. Development of efficient electro-conductive fabrics, to optimize the functional performance of heating, presence detection and other safety and comfort functions of the VEC.

SG 7. Reduction of CO2 emissions of the proposed global process by 50% (KPI-3) compared to current production processes for alveolar polymers and functional tissues.

Research into active degassing moulds, for the production of ultra-light PUR foams for comfort and acoustic absorption of the VEC (Target d<40g/l)

Research into eco-efficient PUR and PPE production processes. Zero Defects.

Research into PUR Formulae.

Research inyp PPE Formulae

Research into BIO textile treatments.

Research into the conductive efficiency of electro-conductive fabric.

Development of prototypes and technological demonstrators of VEC components that incorporate the technological evolutions obtained.

Research into data analytical techniques aimed at detecting anomalies in process.

Project: Project: “CENTAURO” Project RESEARCH into the formulation and PRODUCTION OF ECO-SUSTAINABLE ALVEOLAR POLYMERS FOR the ELECTRIC VEHICLE Start Date: 01/07/2022 // End Date: 30/09/2025 Budget allocated: €627,064 Co-financing granted: €372,490

ATIR 2.0

The ATIR 2.0 project will contribute to the development and streamlining of a new tidal energy platform. New renewable energy initiatives like this are critical if we are to meet the EU’s environmental targets for 2030 and 2050, meaning investments are needed to further optimise these systems until they are commercially viable. If successful, at the end of the project it is expected that ATIR 2.0 may be on track to be a new renewable energy alternative and that it will contribute to the improvement of scientific knowledge in this field. Therefore, it can be said that the ATIR 2.0 project is fully aligned with the EU’s Blue Economy and Green Deal strategies.

The energy of marine currents is the best prepared for the market of the different marine energy technologies due to its maturity and its advantages over other marine energy technologies, for example, its high level of predictability and standout performance. The potential tidal resource available in the waters around the United Kingdom is 29 TWh/year, which is equivalent to around 10% of the global available resource of marine currents. In Spain, the estimated tidal resource is 1,358 TWh/year, which is equivalent to 5 nuclear power plants.

Magallanes Renovables, which is a Spanish limited company engaged in the promotion, construction and running of technological solutions capable of exploiting the energy of marine currents in an efficient, reliable and profitable way. The partners AITODETEC and TECDESOFT have been working together on this development for more than a decade. In the ATIR 2.0 project, TECDESOFT will work on the design of the entire electrical section, the control strategy and the implementation of the Digital Twin that will allow for the entire set, the simulation in the different generation scenarios and the training and training of operators to be validated.

Tidal energy is the future. Clean, green and 100% predictable, knowing how much and when electricity will be produced will be key in a future in which the energy mix will be governed by renewable energies 2.0.

Project: “ATIR 2.0” DEVELOPMENT, DESIGN AND CONTROL PLATFORM OF THE SPANISH RENEWABLE MARINE ENERGY PLATFORM Start Date: 01/11/2022 // End Date: 31/12/2024 Budget allocated: €597,601 Co-financing granted: €433,858

RESUAIR

This project’s primary aim was to generate an ADVANCED SELF-CONTAINED RESPIRATOR. Through the connectivity with which we have endowed RESUAIR, several units can be operated at the same time from a centralised point.

It acts an indefinite mechanical actuation device of Ambu resuscitator bag or similar. It can work with different resuscitating balloons, both disposable and reusable. Allows use with both atmospheric air and oxygen supply and storage.

In this project, Tecdesoft has sought to endow it with all its knowledge to the health service.

Project funding allocated: 81.100,22 €

This project is subsidized by GAIN “Axenda de Innovación” and by the DEPARTMENT OF THE ECONOMY, EMPLOYMENT AND INDUSTRY.

S3RV1C10 5.0

The primary aim of the 53RV1C10 5.0 project is the incorporation of a COBOT (collaborative robot) to the service sector to help and collaborate with hospitality workers in carrying out the monotonous, mechanical and impersonal operations that are carried out in their work.

It is intended to offer a new and better service to people with the creation of a new concept. Service 5.0.

Project funding:This project is subsidised by the State Secretariat of Education and Vocational Training, grants are offered as tenders to undertake applied innovation and knowledge transfer project in Vocational Training of the Educational System. Featuring co-financing from the European Social Fund within the framework of the Operational Programme for Employment, Training.

SMART4SLATE

This project’s main aim is based on the transformation of the production process of natural slate with a holistic approach of SMART and Sustainable Production 4.0 that is characterized by being creative, intelligent and human.

Cupa GROUP (Large Galician Company, world leader in natural slate for roofs and therefore tractor company): Cupa Innovación (in the role of Project Leader), Cupa Pizarras, Cupa Ingeniería.

CETIM (National Technological Centre belonging to ATIGA, expert in the characterization of materials, sustainability and technology transfer)

TECDESOFT (Galician SME with the seal of innovative SME expert in industrial digitisation and implementation towards Industry 4.0)

SPECIFIC PROJECT AIMS

Creation of a digital model of a natural slate production plant for monitoring, which allows answering questions about the optimal slate references to be produced in order to reduce stocks, logistics and production costs, improve knowledge and asset management and reduce operating and maintenance costs.

Project Progress

Annuity 1

The project begins with the requirements analysis of each of the proposed activities.

The sensorisation deployment works of the pilot plant are carried out, alongside the Edge Computing and fog Computing works. The implementation and improvement of the platform begins.

Annuity 2

During the second year, part of the work, already started in year 1, of the production monitoring platform completed.

Design work and scalability testing of the platform began.

Data analytics AI work began, in the optimization of production planning.

Annuity 3

Improvement works of the production monitoring platform and the design and validation works of the scalability plan.

Work on the production planning optimisation solution completed.

After concluding all the activities, the SMART4SLATE project has ended with satisfactory results.

Project funding: This project is subsidised by the Galician Innovation Agency within the framework of the 2020 call for bids on the Factory of the Future, Smart and Sustainable Factory of Industry 4.0 aid programme. T he aid granted under this Programme has been co-financed by the European Regional Development Fund (ERDF). The project is supported by the Second Vice Presidency and the Ministry of Economy, Business and Innovation.

NERO

NERO will develop advanced monitoring systems based on non-invasive embedded sensors, which allow to carry out manufacturing and repair processes of more efficient and environmentally sustainable composite structures, and which in turn, provide information on the structural behaviour throughout the service life of the manufactured structures.

It came into being from the need to control and monitor the manufacturing, repair and service life processes of structures produced in composite materials, an area in full expansion.

Project financing: 100% co-financed from ERDF funds. Subsidised by the Galician Innovation Agency, it has the support of the Ministry of Economy, Employment and Industry (IN852A 2018/47).

Click on the image to download further information.

MEmpHIS

MEmpHIS is a project whose main purpose is the development of a distributed monitoring and control platform (DMCP) for thermal power plants. It consists of 3 technologies:

- Fibre Optic Sensors

- Artificial Intelligence

- Decentralised control architecture CPS.

Participating companies:

ENDESA · TECNATOM · ENCE · TECDESOFT · AIMEN

Project funding: RETOS-COLABORACIÓN call for bids, financed by the Ministry of Economy, Industry and Competitiveness, the State Research Agency and the ERDF allocation.

Click on the image to download all information.

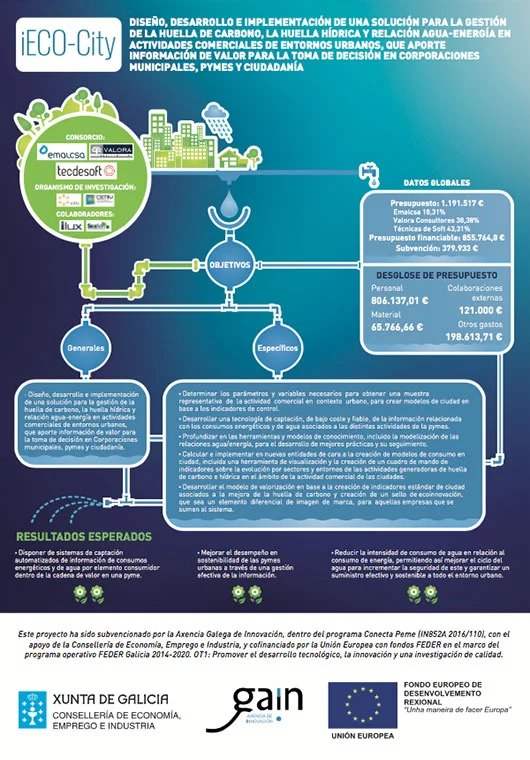

iECO-CITY

iECO-CITY is an innovation project focused on the design, development and implementation of a solution for management of carbon footprints, water footprints and water-energy ratio in commercial activities in urban settings, which provides valuable information for decision making in municipal corporations, SMEs and citizens. As a result of the project, users will be able to:

- Have automated systems on-hand for capturing information on energy and water consumption by consumer element within the value chain in an SME.

- Improve the sustainability performance of urban SMEs through effective information management.

- Reduce the intensity of water consumption in relation to energy consumption, thus allowing for the water cycle to be improved as to increase its security and guarantee an effective and sustainable supply to the entire urban environment.

The iECO-CITY consortium consists of the following companies:

EMALCSA · TECDESOFT · VALORA CONSULTORES

Aid granted: €193,950.01 Project co-financed by the European Regional Development Fund (ERDF) within the framework of the ERDF Galicia 2014 – 2020 operational programme.

Click on the image to download further information.

WATERWATCH

Implementation of an EARLY WARNING SYSTEM on POLLUTION in inland waters through the determination of pioneering solutions in:

- Real-time remote control of DISCHARGES and CONTAMINANTS in water bodies.

- Development of TOOLS for integration into a control PLATFORM (Smart-city network and Environmental Alert network).

- Design and implementation of innovative strategies and methodologies for ANALYSIS at detection level (biosensors) and information processing (neural networks).

- Through the design and development of an integrated remote control network: INFORMATION systems for monitoring and EARLY WARNING.

- STANDALONE modular monitoring STATIONS.

- STANDALONE ECOTOXICITY detection DEVICES running via biosensors.

Participating companies:

AVANZA-LAB · ECONTROL · TECDESOFT · EMALCSA

Aid granted: €196,195.74 Project co-financed by the European Regional Development Fund (ERDF) within the framework of the ERDF Galicia 2014 – 2020 operational programme.

Click on the image to download further information.

COWARE

Development of the technologies necessary for the simultaneous decomposition of a homogeneous mixture of two or more organic substrates, with the aim of:

- Maximising biogas production.

- Maintaining process stability.

- Obtaining the optimal mixture of substrates.

- Performing a diagnosis of the stability of the process.

Aid granted: €151,253.30 Project co-financed by the European Regional Development Fund (ERDF) within the framework of the ERDF Galicia 2007 – 2013 operational programme.